ALOE-VERA FABRIC

Step into a world of mindful fashion with our plant-based fabrics, crafted for those who care about beauty and the planet. At House of Parvi, every piece is made with love, responsibility, and artistry that honors nature.

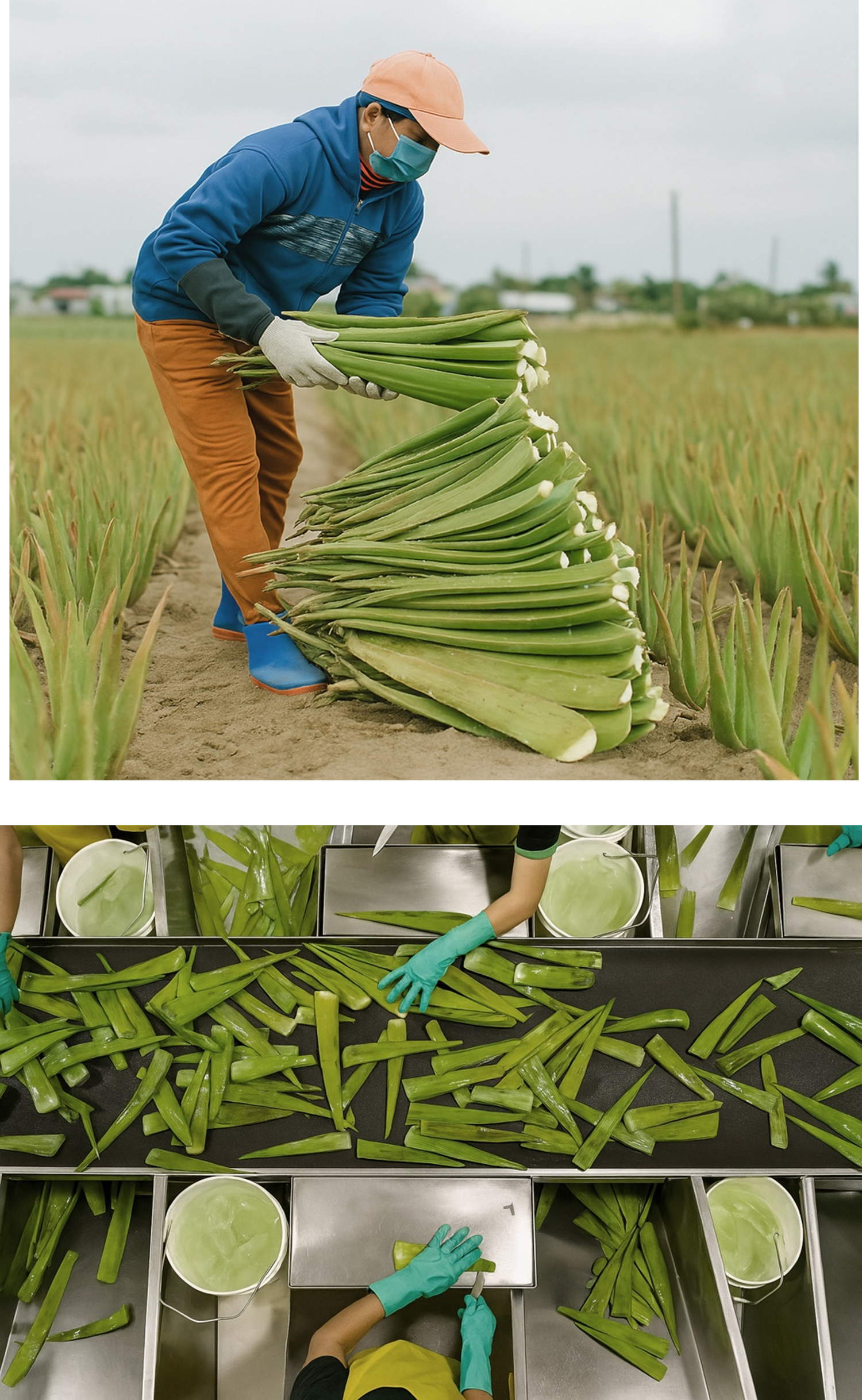

HARVESTING AND EXTRACTING

Aloe-vera plants are grown for both gel and fiber. Mature leaves are harvested, usually when plants are 2–3 years old.

Aloe-Vera leaves are decorticated to separate fiber from the fleshy parts.

CLEANING & DRYING

Extracted fibers are washed to remove sticky sap, gel residues, and impurities.

In some processes, enzymes or mild alkali are used to degum the fibers and

make them softer.

Clean fibers are sun-dried or machine-dried to reduce moisture and prevent rotting.

GATHERING & FIBER PREPARING

Extracted fibers are washed to remove sticky sap, gel residues, and impurities.

In some processes, enzymes or mild alkali are used to degum the fibers and

make them softer.

Clean fibers are sun-dried or machine-dried to reduce moisture and prevent rotting.

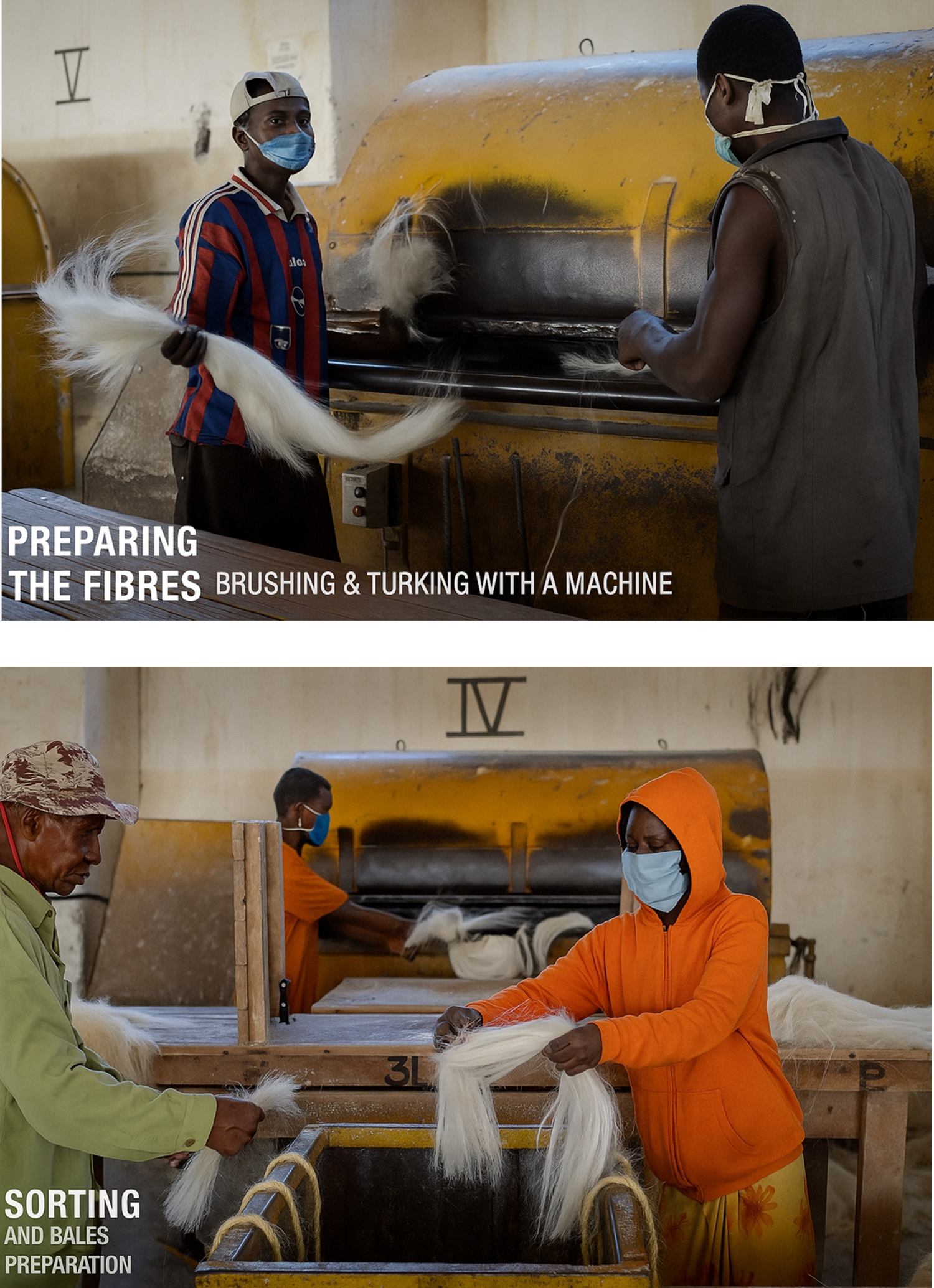

BRUSHING & SORTING

Dried fibres are brushed/combed to align them, remove short fibres and improves smoothness and sorted into three qualities A, B & C.

TOWING & SPINNING

The prepared fibers are spun into yarns using hand-spinning wheels or industrial machines.

Since aloe fibers are fine and silky, they can be spun into soft, smooth threads.

BLENDING & WEAVING

Because aloe fibers are delicate, they are often blended to increase strength and durability with cotton, silk, wool, polyester or kept pure aloe-vera fiber Yarns are woven on looms or knitted into fabrics.

The result is a lightweight, breathable, skin-friendly fabric often marketed as “wellness textiles.